In version 5.5, the Design Module provides an entirely new sketching tool for easier creation and more versatile parametric control of geometry models. Powell, M.J.D.: A view of algorithms for optimization without derivatives.COMSOL announces the latest version of its COMSOL Multiphysics® software.

(eds.) Advances in Optimization and Numerical Analysis, pp. Powell, M.J.D.: A direct search optimization method that models the objective and constraint functions by linear interpolation. Nelder, J.A., Mead, R.: A simplex method for function minimization.

In: COMSOL Tokyo Conference 2014, Tokyo (2014) Accessed įrei, W.: Optimization with COMSOL multiphysics. Hungarian Standards Institute (2007)ħ/2006 (V.24.) TNM decree on the Determination of the Energy Characteristics of Buildings. Assessment of moisture transfer by numerical simulation. MSZ EN 15026:2007 Hygrothermal performance of building components and building elements.

COMSOL 5.1 MODULE PRICES ISO

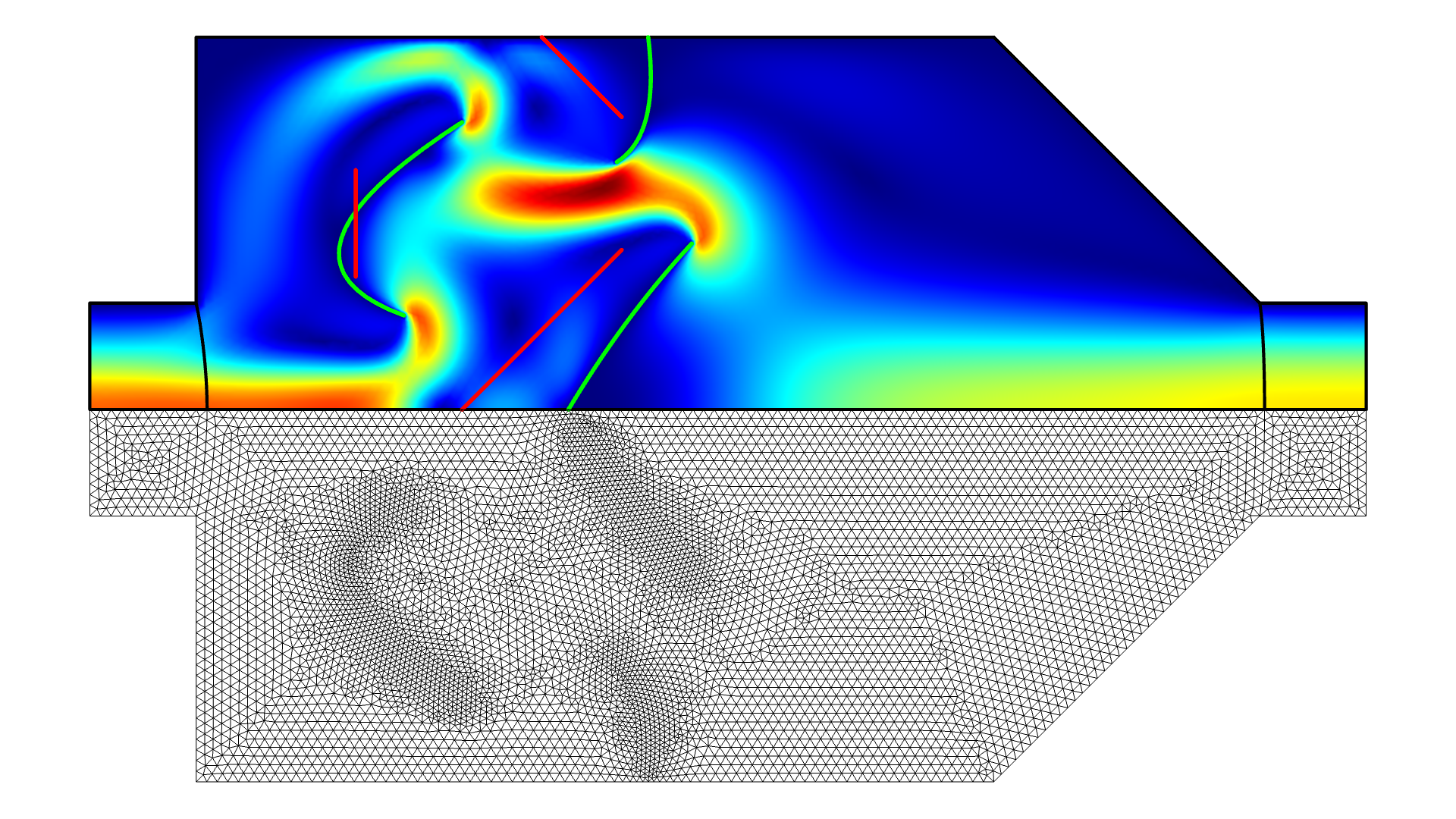

MSZ EN ISO 10211:2017 Thermal bridges in building construction. Thermal resistance and thermal transmittance. MSZ EN ISO 6946:2017 Building components and building elements. IRB Verlag (1995)Ĭomsol Multiphysics 5.3 Heat transfer module user’s guide (2017) One and two-dimensional calculation using simple parameters, vol. Künzel, H.: Simultaneous Heat and Moisture Transport in Building Components. Wienerberger technical data and processing manual. 25, 2254–2262 (2011)īruggi, M., Taliercio, A.: Design of masonry blocks with enhanced thermomechanical performances by topology optimization. Sousa, L.C., Castro, C.F., António, C.C., Sousa, H.: Topology optimisation of masonry units from the thermal point of view using a genetic algorithm. Li, J., Meng, X., Gao, Y., Mao, W., Luo, T., Zhang, L.: Effect of the insulation materials filling on the thermal performance of sintered hollow bricks. Wernery, J., Ben-Ishai, A., Binder, B., Brunner, S.: Aerobrick – an aerogel-filled insulating brick. Zach, J., Novák, V.: Study of the use of vacuum insulation as integrated thermal insulation in ceramic masonry blocks. In: Proceedings of the 4th International High Performance Buildings Conference at Purdue, vol. Setty, A.B.T.P., Shaik, S.: Investigation of dynamic thermal parameters of various insulation filled bricks exposed to periodic thermal variations for energy efficient stuffed bricks design. Pavlík, Y., Jerman, M., Trník, A., Kočí, V., Černý, R.: Effective thermal conductivity of hollow bricks with cavities filled by air and expanded polystyrene. In: Proceedings of the 2nd Central European Symposium on Building Physics, pp. Kočí, J., Maděra, J., Jerman, M., Černý, R.: Effect of cavity filler on the effective thermal conductivity of hollow bricks: a computational analysis based on accurate input data. Zach, J., Hroudova, J., Sedlmajer, M.: Study of hygrothermal behavior of advanced masonry components made with utilization of secondary row materials. Zukowski, M., Haese, G.: Experimental and numerical investigation of a hollow brick filled with perlite insulation. Nagy, B., Orosz, M.: Optimized thermal performance design of filled ceramic masonry blocks. Nagy, B., Tóth, E.: Hygrothermal behaviour of hollow and filled ceramic masonry blocks. Using the presented optimization method in designing masonry blocks leads to more energy efficient structures using the same or even less materials, without increase of producing cost. The study showed that the masonry products designed by optimization have lower thermal transmittance than the reference value. In the paper, the optimization process is presented through the results of mineral wool filled blocks, which gave combined parallelogram and trapezoidal shaped internal geometries depending on the bounds of the optimization. In this study, a new masonry design approach is presented using finite element method and conjugated heat and moisture transfer analysis with derivative-free shape optimization of the internal structural geometry of an existing masonry block to get the best possible hygrothermal performance from the blocks. Manufacturers did not address the optimization of the internal geometry of the insulation filled masonry blocks before. However, the internal structural geometry of these blocks remained simple: producers mostly using only large rectangular hollows to fill with different insulating materials, such as mineral wool, polystyrene or expanded perlite. Due to current energy performance requirements, masonry block producers developed thermal insulation filled masonry blocks to achieve lower thermal transmittance.

0 kommentar(er)

0 kommentar(er)